8 Apr 2024

The power of SMA shift actuators for superior smartphone camera OIS

By Jason Tun, Head of 4W OIS Systems

Shape Memory Alloy (SMA) shift actuators, comprising 4 SMA wires, play an important role in smartphone cameras by providing Optical Image Stabilisation (OIS). SMA actuator technology, characterised by its high force-to-mass ratio, design versatility and lack of electromagnetic interference, offers several advantages over alternative OIS systems, such as Voice Coil Motors (VCM).

The need for image stabilisation

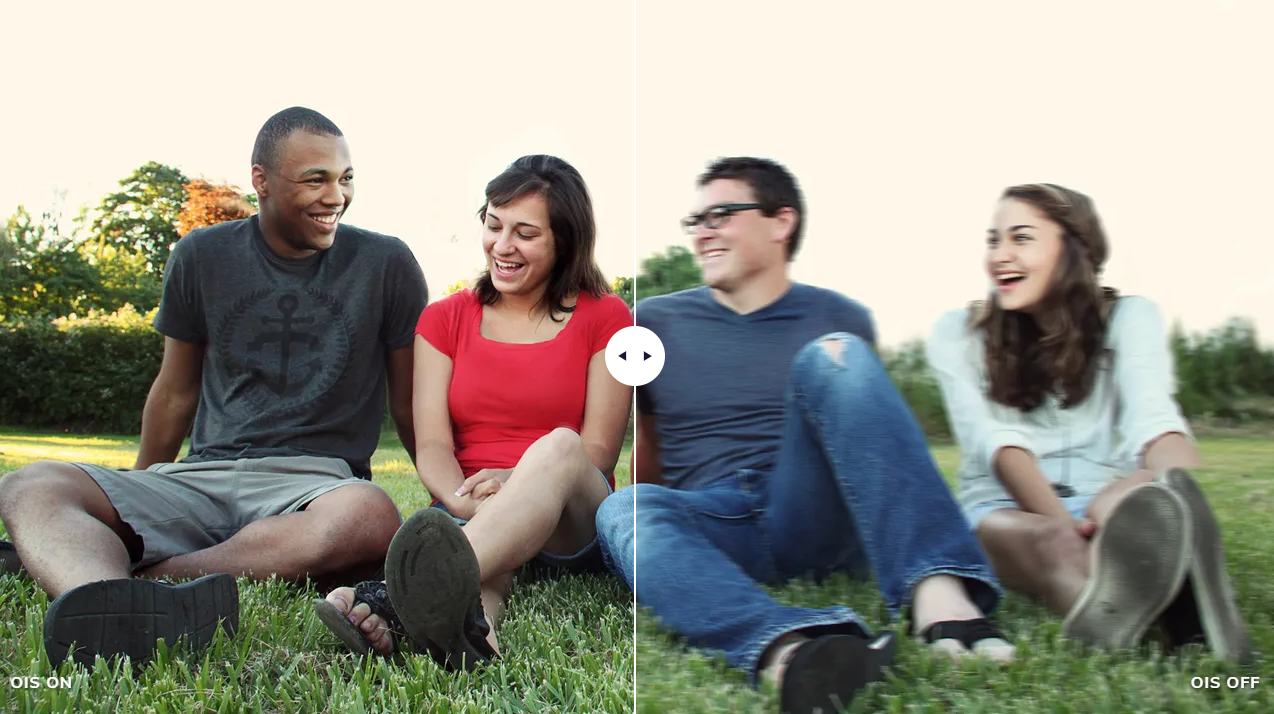

Image stabilisation (IS) is a critical feature for high-end smartphone cameras, addressing the issue of image blur caused by the natural handshake and movement during photo or video capture. By mechanically adjusting the position of the lens relative to the image sensor (or vice versa), the image stabilisation ensures that light is consistently aligned on the sensor, thereby maintaining image sharpness and clarity. The stabilisation is particularly crucial in low-light conditions where longer exposure times can increase image blur. This results in sharper, clearer images and a more reliable photographic experience for smartphone users, making OIS a must-have feature in a growing market segment.

Cambridge Mechatronics Ltd. (CML) is the world-leader in the precise control of SMA wire and offers full systems solutions for SMA-based actuator designs, such as OIS actuators, for the smartphone industry.

Figure 1: OIS on vs OIS off

Figure 1: OIS on vs OIS off

OIS and EIS

OIS and Electronic Image Stabilisation (EIS) are two distinct methods used in smartphone cameras to compensate for camera shake, each with its unique approach and benefits.

- OIS is a mechanical system, using actuators to physically move (shift) typically the camera lens or sensor, thereby stabilising the image in real-time. This method directly addresses the root cause of image blur by adjusting the optics to compensate for hand movements, making it highly effective for stills photography where preserving image detail is crucial – especially in low-light conditions.

- EIS, on the other hand, is a digital technique that stabilises video by cropping and shifting the captured frames in post-processing. While EIS stabilises frame-to-frame jitter in video capture, it results in a reduced field of view and cannot remove motion blur on still photos or individual frames in a video, leading to reduced resolution. The effectiveness of EIS is limited in low-light conditions, where blur on each frame becomes significant due to slower shutter speeds and/or frame rates.

The most comprehensive camera systems combine both OIS and EIS, utilising the physical correction of OIS for sharp, high-quality images and the digital prowess of EIS for enhanced video stabilisation. This combination ensures maximum stability and image clarity across both stills and videos.

SMA shift actuators for OIS

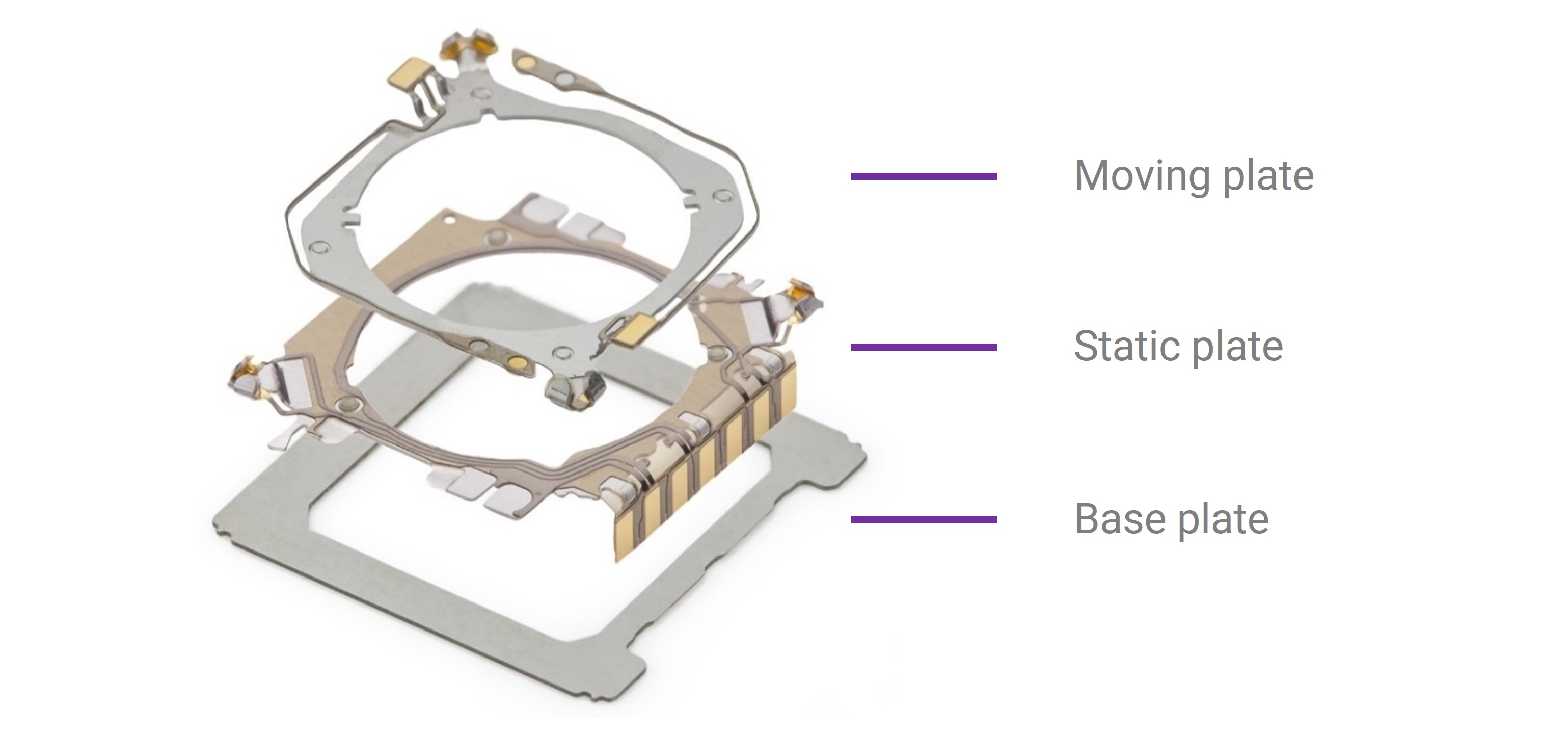

Using CML’s patented SMA technology, the 4-wire actuator design enables both sensor shift and lens shift OIS capabilities. In its basic form, the actuator comprises a base plate, static plate, moving plate, and four SMA wires.

Figure 2: Exploded view of a SMA Lens Shift OIS actuator (SMA wires not shown)

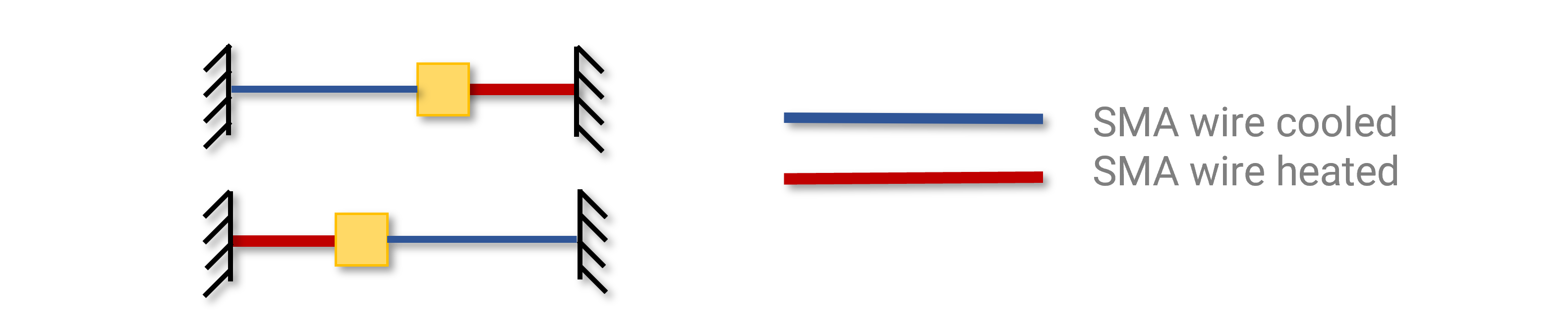

The SMA shift system features a straightforward design with four 25um diameter SMA wires in a square configuration around the camera lens or image sensor. The SMA wires contract when heated and expand when cooled, thus adjusting the sensor’s position. Fast and precise control is achieved through CML’s unique controller IC and software, delivering top-of-the-range OIS performance.

Figure 3: SMA wires contracting and extending when heated and cooled

Figure 3: SMA wires contracting and extending when heated and cooled

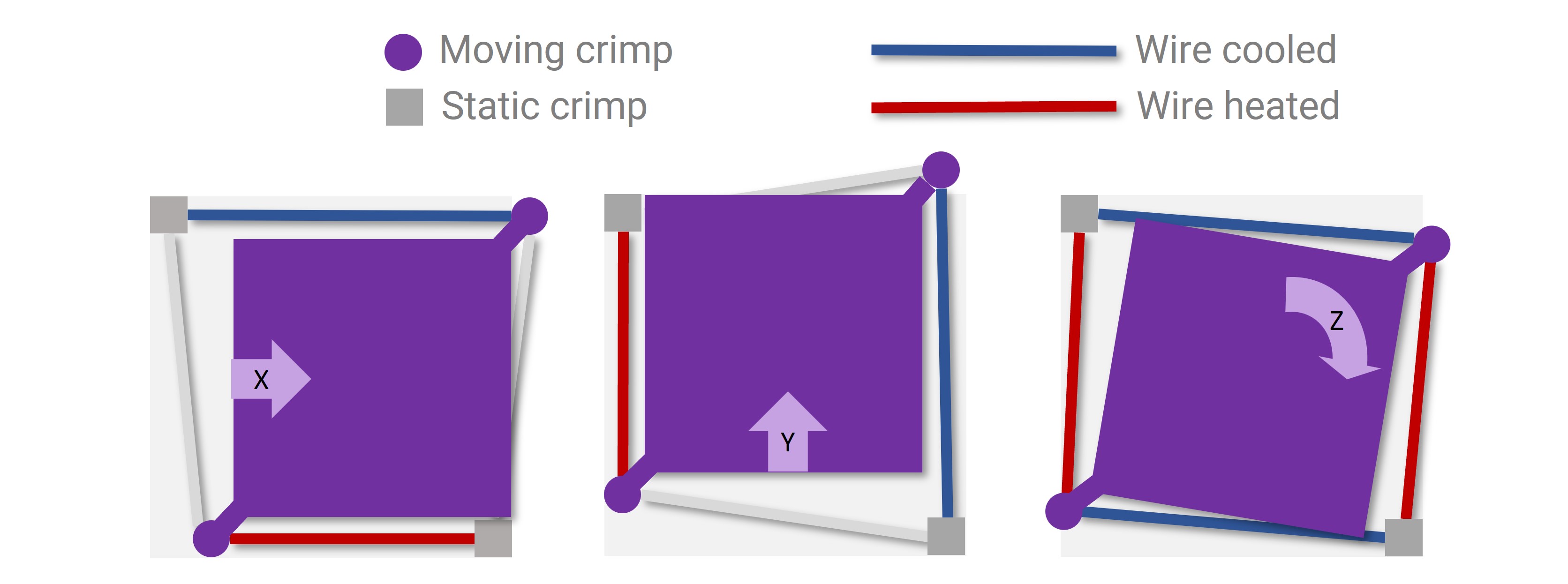

In the 4-wire actuator design, two of the SMA wires are responsible for controlling movement along the X-axis, the other two for the Y-axis, and all four wires work together to control the roll motion. This arrangement allows for precise and independent control of each axis, which is crucial for effective image stabilisation.

Figure 4: SMA Sensor Shift OIS operating principles

Figure 4: SMA Sensor Shift OIS operating principles

The SMA-based design not only overcomes limitations of VCM systems but also offers a more compact footprint (25-35% smaller) and reduced height. Unlike VCM, which requires position sensing technologies, CML’s solution is able to use the SMA wire as an actuator and a position sensor concurrently (through wire resistance measurements) – so there’s no need for Hall sensors. The high force-to-mass ratio generated by SMA wires allows for a diverse range of interconnect materials to be used for sensor shift designs, providing handset makers with greater design and assembly flexibility. Additionally, the absence of electromagnets in SMA technology eliminates magnetic flux, making it ideal for modern handsets packed with magnetically sensitive components.

CML’s comprehensive system integration support encompasses the actuator, controller chip (CM824), and patented firmware. The precise motion of the actuator is in response to the Inertial Measurement Unit (IMU – comprising a gyroscope and accelerometer) in the smartphone handset, which communicates directly with the controller IC. Read more about the SMA control system architecture for OIS.

SMA Lens Shift OIS

When configured for Lens Shift OIS, the actuator focuses on moving the lens in relation to a stationary image sensor. This movement compensates for camera shake by adjusting the lens position to ensure that the image projected onto the sensor remains stable, thus reducing blur in X and Y directions (up/down and sideways).

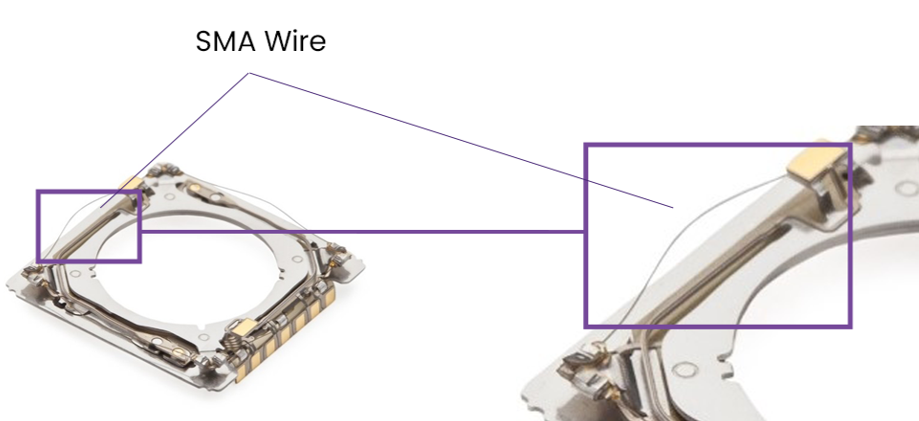

Figure 5: Magnified view of the SMA wire in the Lens Shift OIS actuator

Figure 5: Magnified view of the SMA wire in the Lens Shift OIS actuator

SMA Sensor Shift OIS

The Sensor Shift OIS design involves inverting the Lens Shift setup. Instead of moving the lens, the image sensor is shifted. This adjustment is particularly advantageous because the sensor shift configuration not only compensates for X and Y axis movements but also introduces the ability to compensate for roll – rotation around the Z-axis. This is made possible due to the unique arrangement of the SMA wires; by manipulating the tension in opposing wires, the actuator can induce a rotational movement, as shown in Figure 4.

CML’s shift actuator designs are equally effective for moving the image sensor or the heavier lenses, due to the high force-to-mass ratio capabilities of SMA.

Video of SMA Sensor Shift OIS in motion

Design simplicity and maturity

CML's SMA Shift OIS actuator technology has achieved significant success since its high-volume mass production began in 2019. To date, CML’s OIS (and autofocus) actuator systems have shipped in over 75 million units across several leading smartphone handset brands, with many of the cameras receiving top-scoring marks in independent DXOMARK testing.

The SMA Shift OIS technology simplifies the design of OIS actuators in several key ways:

Compactness: SMA Shift OIS is designed with a minimal number of components, which can fit around the outside of lens and under the autofocus (AF) actuator. The SMA wire itself acts as a position sensor, so no additional components or bulky electromagnets are required. This results in a more compact form factor, making it suitable for slim devices and folding phones.

High force-to-mass ratio: This characteristic allows SMA actuators to handle heavier lens assemblies, such as those with integrated variable apertures, without performance degradation. SMA's ability to move components weighing several grams is particularly advantageous. This high actuation force is achieved without the need for bulky magnets and coils, streamlining the design. Unlike VCM, power and performance are independent of the camera posture, and vigour of shake.

Elimination of magnetic interference: CML’s SMA technology solves the problem of magnetic interference in smartphones. SMA Actuators do not rely on magnets, which allows for greater design flexibility, including placement near other EMI-sensitive components.

Scalability: The actuator designs are scalable for all image sensor formats, supporting up to 1” (at the time of writing), making them adaptable to different camera specifications without significant redesign efforts.

Conclusion

The integration of 4-wire SMA shift actuator technology for OIS offers numerous benefits, including compact design, no magnetic interference, high force-to-mass ratio, rotational control, and the potential for increased OIS compensation angles. As smartphone cameras continue to evolve, SMA actuators are expected to play a significant role in enhancing image stabilisation and overall photographic performance, making them an indispensable component in the future of mobile photography.

By providing an actuator system that reduces complexity, size and component count while providing high performance and flexibility, the SMA shift OIS technology offers a streamlined and efficient approach to implementing OIS for smartphones and other compact devices.

About CML: Cambridge Mechatronics Limited (CML) is a world-leading developer of mechanical, optical, electrical, silicon, and software designs for system-level solutions using its Shape Memory Alloy (SMA) platform technology. ACTUATOR SOLUTIONS based on SMA wire (thin as hair) can be controlled to submicron accuracy. These actuators are particularly suited to applications requiring high precision and force levels, in a fast, compact, and lightweight design.

For more details about SMA technology and Cambridge Mechatronics, please GET IN TOUCH.