1 Jul 2023

CML’s Shape Memory Alloy technology solves a major problem with magnetic interference inside premium smartphones

By Robin Eddington, Head of Product Design

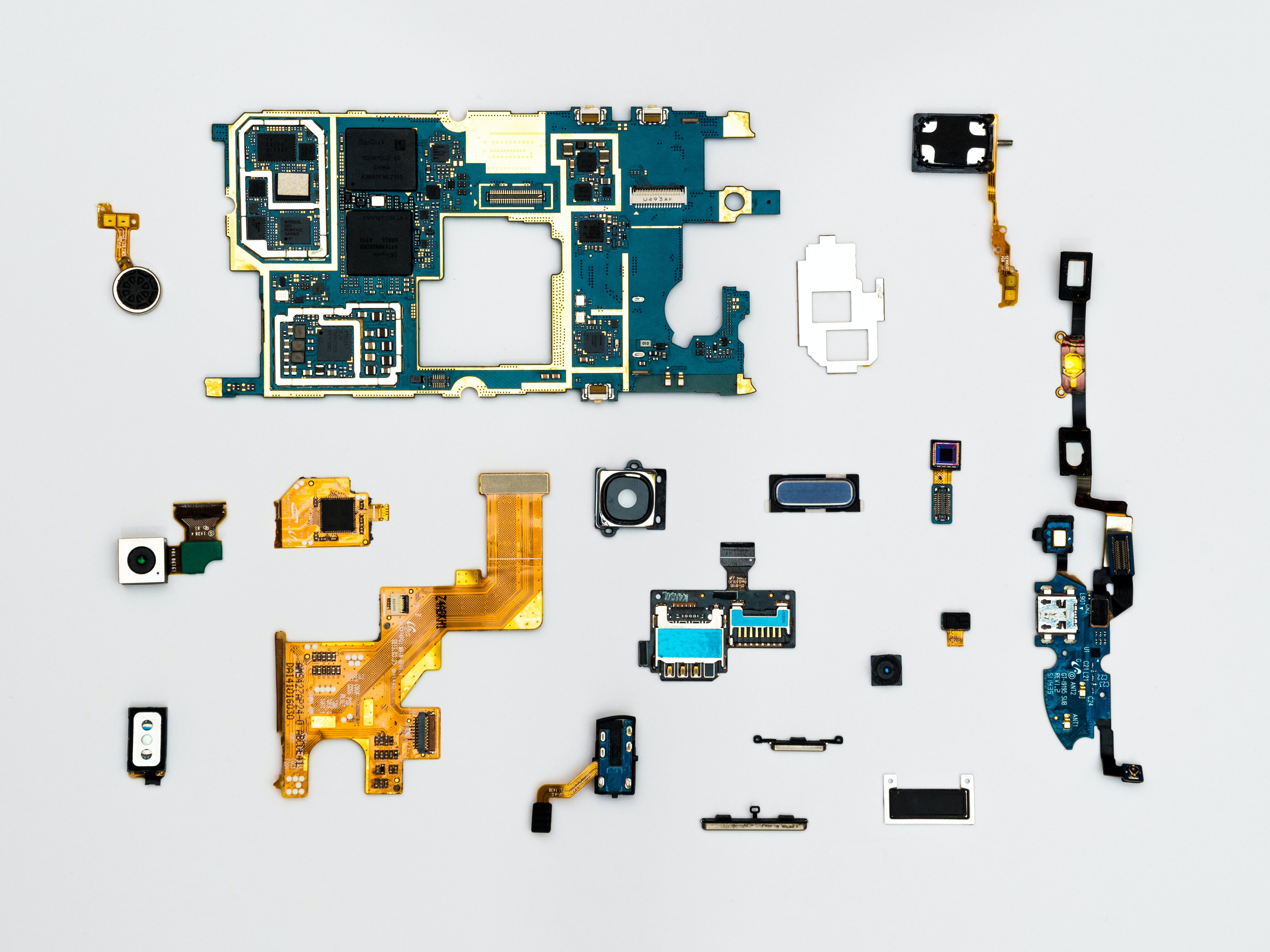

Premium smartphones are continuing to feature an increasing number of magnetically sensitive components and optical image stabilization (OIS) and autofocus (AF) enabled cameras per device. This is causing an ever-growing challenge for smartphone OEMs who need to take into account the magnetic interference impact of all OIS and AF camera modules using voice coil motor (VCM) technology. This is further complicated by the emergence of variable aperture actuators which are closely integrated into the camera module and magnetic hinges in folded phones.

A typical VCM-based OIS camera system might use 4 neodymium rare-earth magnets per actuator. The actuator manufacturer can carefully design the actuator to ensure no unexpected magnetic interference within the camera module, but with multiple actuators per handset packed closely together, the smartphone manufacturer must also take into account how each camera module will affect each other, which often means having to position them differently, leaving gaps between camera modules or other critical components such as the vibration motors or speakers. The magnetic interaction between separate components can be difficult to simulate, and with time-to-market pressures, it ultimately leads to compromises with the design.

The recent trend of foldable handsets has conflated the problem further, as often the latch mechanism that keeps the handset shut uses much more powerful magnets than those found in the camera module. Magnets also cause trouble for the designers of smartphone accessories such as cases. Apple provides guidelines recommending that accessory designers avoid the use of magnets and metal components to avoid interference with the AF and OIS operation.

To offer superior low-light performance, smartphones are adopting bigger image sensors and correspondingly, wider lenses featuring larger apertures. This design choice facilitates greater light absorption, producing better quality images in low light. However, large lens apertures lead to a narrower depth-of-field (DoF) which can compromise picture and video quality. Therefore, variable aperture actuators are increasingly being deployed in high-end smartphone cameras as they bring the benefits of true depth of field control not being subject to the artificial blurring from software processing. The variable aperture is placed on top of the lens close to the AF/OIS actuator(s). When all these actuators are VCM based, the designers needs to account for complex magnetic interference issues.

Magnets are inherent to the operation of a VCM actuator, and thus cannot be avoided. Cambridge Mechatronics’ Shape Memory Alloy (SMA) actuators do not use magnets and therefore give much more flexibility in the design process. Smartphone OEMs can position CML-enabled camera modules where they like without fear of interfering with other components or accessories which do contain magnets. Over 50 million SMA actuators have now shipped, including in an increasing number of folded phones, such as the Xiaomi Mix Fold 2 and 3.

ABOUT CML: Cambridge Mechatronics Limited (CML) is a world-leading developer of mechanical, optical, electrical, silicon and software designs for system-level solutions using its Shape Memory Alloy (SMA) platform technology. Solutions such as ACTUATORS based on SMA wire (which is as thin as a human hair) can be controlled to the accuracy of the wavelength of light. These actuators are particularly suited to applications that require high levels of precision and force, in a fast, compact and lightweight design.

For more details about SMA technology and Cambridge Mechatronics, please get in touch.