21 Mar 2024

Optimising Shape Memory Alloy AF and OIS camera performance: SMA’s Control System Architecture

By Chris Avery, Head of Efficiency and Tools

Cambridge Mechatronics Ltd. (CML) has established itself as a leader in providing precise control techniques for Shape Memory Alloy (SMA) Optical Image Stabilisation (OIS) and Autofocus (AF) actuator solutions, primarily used in smartphone cameras. This article provides an overview of the control system architecture in relation to CML’s SMA OIS and AF actuators in compact camera systems. The architecture used is consistent with incumbent technologies, allowing drop-in integration.

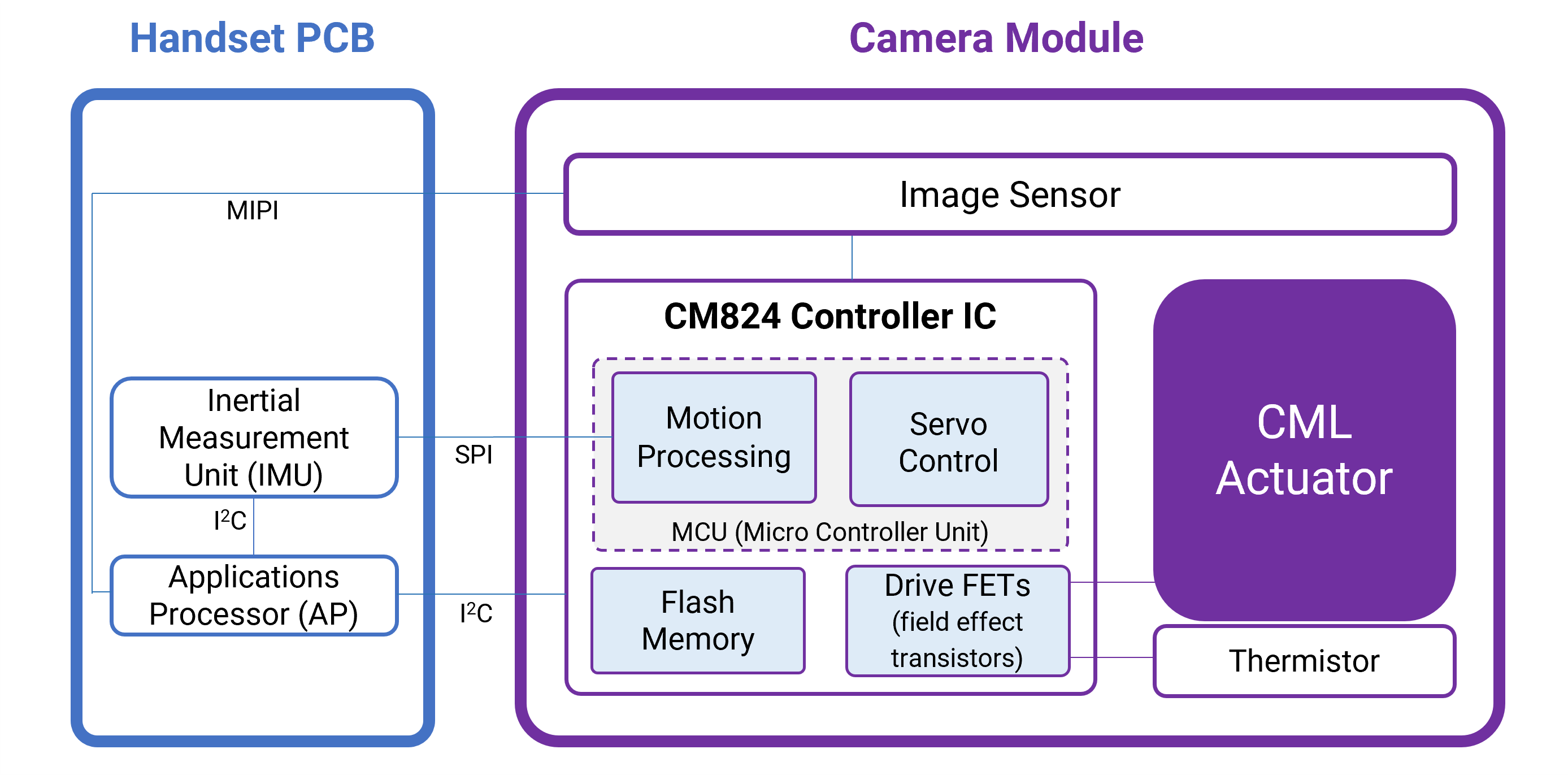

There are several hardware and software components involved in controlling smartphone camera OIS and AF actuators. Together with the handset Application Processor (AP), CML’s actuators and controller Integrated Circuit (IC) chip expertly manage AF and OIS demands. CML’s IC integration with gyro and accelerometer sensors, known as an Inertial Measurement Unit (IMU), facilitates real-time OIS and AF adjustments.

CML’s integration of these components and the optimisation of the control algorithm for each actuator design ensures optimal performance in terms of speed and precision. A diagram highlighting the actuator control system architecture for AF and OIS functions is shown below.

Figure 1: SMA actuator control system architecture

Figure 1: SMA actuator control system architecture

The subsequent sections introduce the components highlighted in the control system diagram above, detailing their roles in managing an SMA camera actuator for enhanced AF and OIS. Note that the camera lens, despite its significance in photography, falls outside the scope of this article.

Handset PCB

The handset main Printed Circuit Board (PCB) serves as the foundation for mounting and integrating electronic components, including some of those responsible for camera functionality. It hosts the AP, the IMU, and the board-to-board connector for the camera module, among other critical components. The PCB's design and layout are crucial in ensuring efficient communication between these components, minimising latency, and optimising the camera's response time to user commands and environmental changes. CML provides detailed documentation for SMA applications and helps customers with the review process.

Inertial Measurement Unit (IMU)

The IMU is an important component in modern smartphones, especially for camera modules requiring OIS. It combines gyroscopes and accelerometers to detect motion and orientation changes with high precision. The IMU's data is fundamental in determining the real-time adjustments needed for OIS, allowing the camera actuator to compensate for shake motion.

The IMU interfaces with CML’s CM824 controller IC using an SPI bus to facilitate a low latency, direct communication channel with the IMU, enabling precise control over the camera's mechanical adjustments for focus and stabilisation.

Application Processor (AP)

The application processor acts as the brain of the smartphone camera system, processing data from various sources, including the image sensor and CML’s CM824 controller IC. It runs the camera application, processes images and makes decisions on AF and OIS adjustments. Typically, the processor's efficiency in handling these tasks directly affects the camera's performance, making it a critical component in the smartphone's overall camera system.

In systems utilising CML's SMA actuators, the CM824 controller IC can alleviate some of the processing burden on the application processor. Based on input from the AP, the controller IC can manage the SMA actuators’ adjustments of lens or sensor positions for focus and stabilisation, utilising CML's precision control algorithms. By offloading some of the computational demands to CML's dedicated controller IC, the system achieves a more efficient distribution of tasks, leading to quicker response times and potentially reduced energy consumption.

Camera module

The camera module is where the majority of the photographic components are located. It houses the image sensor, SMA actuators, lenses, and more. The precision with which it adjusts focus and stabilises images is greatly enhanced by the SMA actuators controlled by CML's controller IC.

Let’s take a closer look at the anatomy of the main camera module control components as shown in Figure 1.

Image Sensor

The image sensor is a critical component responsible for converting light into electrical signals, creating the digital image. The design specifications significantly impact the image quality.

The image sensor's role extends into the operations of AF and OIS systems. In AF mechanisms, the sensor's output is analysed by the application processor to discern focus accuracy, informing lens adjustments to achieve optimal sharpness.

AF systems operate based on a simple optical principle: for an image to appear sharp, light from the subject must be converged precisely on the image sensor. The quality of the image is also dependent on the area of the image sensor. A larger area gathers more light enabling a higher quality image. It is worth noting that SMA actuators deliver a high force-to-mass ratio, enabling larger image sensors to be used without unacceptably large actuators or high power usage.

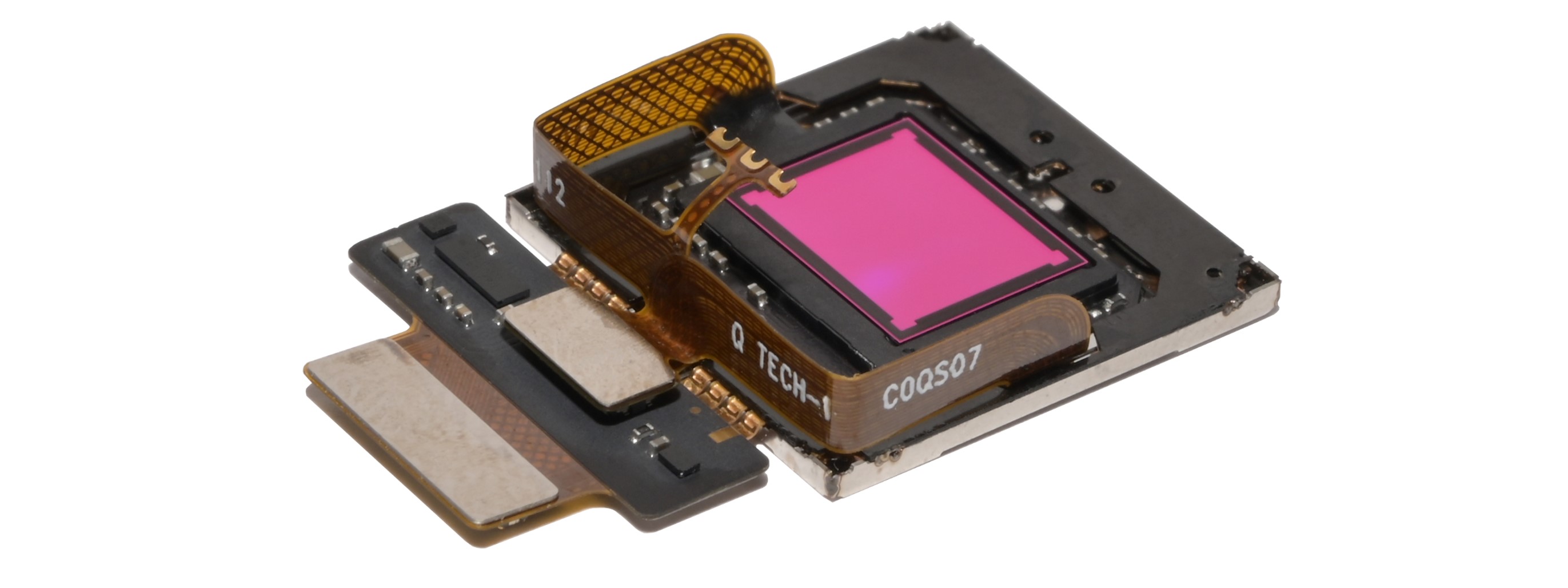

Figure 2: Image sensor with an SMA sensor shift OIS actuator

Figure 2: Image sensor with an SMA sensor shift OIS actuator

OIS works by mechanically compensating for camera movements (in the X- and Y-axes) in real-time to maintain the image's sharpness and clarity. The technology achieves this through two primary methods: actuators moving the lens assembly or adjusting the position of the image sensor relative to the lens. By shifting the position of the image sensor, the OIS system can compensate for movement in the X and Y axes as well as handset roll.

CM824 controller IC

CML's CM824 controller IC is a specialised chip designed to precisely control the SMA actuators. It interfaces directly with the IMU and the application processor, receiving data about motion and adjusting the actuators accordingly. The CM824's ability to rapidly process information and control the actuators with high precision is central to the effectiveness of CML's SMA platform in delivering superior camera performance.

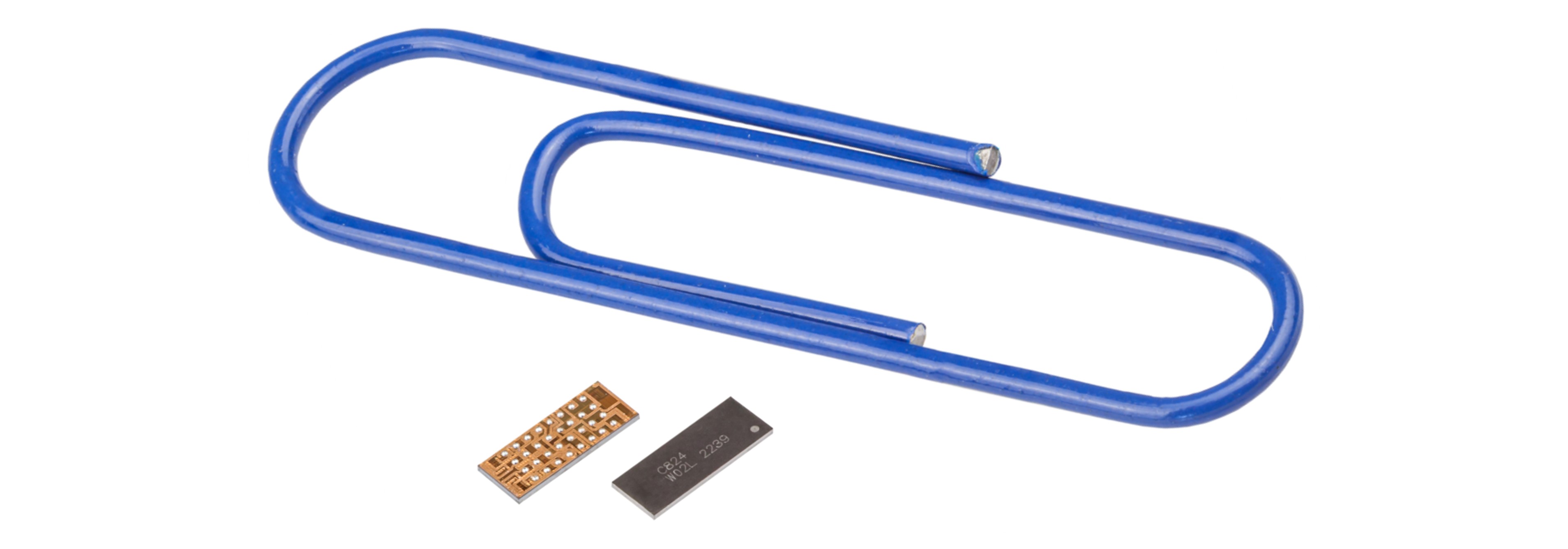

Figure 3: CM824 IC next to a paper clip for a size comparison

The CM824 controller IC incorporates 4 core functions:

1. Motion processing

Motion processing involves analysing data from the IMU to distinguish between intentional movements, such as panning, and unintentional shakes that need to be compensated for by OIS. This process is crucial for determining how the SMA actuators should adjust the camera module to stabilise the image. Advanced algorithms within the CM824 controller IC perform this processing, ensuring good suppression over a larger range of frequencies than competitive algorithms.

2. Servo control

The servo controller in SMA camera systems involves a closed-loop control mechanism, where continuous feedback is used to adjust the actuator's position, speed, and acceleration. This loop ensures the system's output, the actuator's movement, closely follows the input command, derived from the camera's application processor, the IMU and the actuator’s SMA wire.

CML has developed algorithms to accurately interpret feedback from the actuators’ SMA wire resistance, enabling the wire itself to function as a positional sensor for the actuator. Removing the need for position (Hall) sensors reduces the product Bill of Materials (BOM) and simplifies the manufacturing assembly process compared to incumbent solutions. The SMA wire resistance feedback is continuously analysed to assess the discrepancy between the desired actuator position (or speed) and the actual position. The servo control algorithms are designed to optimise the SMA actuator's response to real-time adjustments.

The servo control system for SMA actuators comprises a combination of non-linear control methodology, mechanical engineering, and advanced computational algorithms, all orchestrated to enhance the precision and performance of camera autofocus and stabilisation. As SMA actuators typically have higher resonant frequencies than magnet and coil based designs, CML’s control loop can be run at a lower frequency.

3. Flash memory

Flash memory serves as a non-volatile storage solution for the critical control algorithms necessary for the SMA actuators' operation. This includes the servo control algorithms and motion processing logic. The use of flash memory enables the firmware to be executed instantly when the camera app is switched on.

Traditionally, camera modules utilised a separate Electrically Erasable Programmable Read-Only Memory (EEPROM) chip to store image sensor calibration data and other necessary information. CML's system integrates this functionality into the CM824 controller IC, reducing the number of components required in the camera module. This integration simplifies the module design, reduces costs, and streamlines the manufacturing process.

4. Drive FETs / Power Delivery Unit

Drive Field-Effect Transistors (FETs) within the CM824 controller IC utilise Pulse Width Modulation (PWM) to control the power delivered to Shape Memory Alloy (SMA) actuators. PWM is an efficient technique that modulates the electrical pulses to control the average power delivered to a load—in this case, the SMA actuators. The CM824 controller IC generates PWM signals with varying duty cycles based on the input from the various components described above. This signal precisely dictates how the drive FETs modulate power to the actuators, aligning the lens or sensor position for optimal AF and OIS performance.

Thermistor

A thermistor is a type of resistor which acts as a thermometer for the SMA actuator system. A thermistor is integrated into the camera module to monitor the ambient temperature changes that occur during the operation of SMA actuators. Thermistors play a crucial role in ensuring the SMA actuator system's reliability and performance under varying thermal conditions. Given that the physical properties of SMA (and consequently their actuation characteristics) can be sensitive to temperature variations, the feedback from the thermistor is vital.

Shape memory alloy actuators

The SMA actuator is the muscle within the camera module ecosystem, optimised for precise AF and OIS movement. The SMA actuator is directed by the camera module through a network of control and feedback mechanisms, orchestrated by the CM824 IC. This network ensures that the actuator can respond dynamically to both mechanical demands for focus and stabilisation and environmental factors.

Figure 4: Selection of SMA actuators for smartphone cameras

Summary

CML designs and delivers a complete SMA system solution that integrates advanced hardware and software to control SMA actuators for autofocus and optical image stabilisation in smartphone cameras. This system fits into existing architectures, offering OEMs and manufacturers a streamlined solution for enhancing camera performance using SMA products. Reduced part count in position sensing and reduction in control loop frequency can be applied using SMA solutions. By focusing on ease of integration and product performance, CML is able to solidify its position as an innovator and leader in the field of SMA actuators for smartphone cameras.

About CML: Cambridge Mechatronics Limited (CML) is a world-leading developer of mechanical, optical, electrical, silicon, and software designs for system-level solutions using its Shape Memory Alloy (SMA) platform technology. ACTUATOR SOLUTIONS based on SMA wire (thinner than hair) can be controlled to submicron accuracy. These actuators are particularly suited to applications requiring high precision and force levels, in a fast, compact, and lightweight design.

For more details about SMA technology and Cambridge Mechatronics, please GET IN TOUCH.