14 Mar 2024

Enabling slimmer smartphone cameras with SMA autofocus

By Dr Marc Scholz, Global Accounts Director

The inherent microscale properties of shape memory alloy (SMA) provide substantial benefits for size-constrained devices, such as smartphones. Cambridge Mechatronics Ltd (CML) is the world-leader in precise control of SMA wire and is at the forefront of SMA camera microactuator systems for the smartphone industry. This article introduces CML's ultra-slim SMA Autofocus (SMA AF) actuator, developed to establish compatibility of leading smartphone camera capability with slimmer devices, including folding phones, through SMA technology.

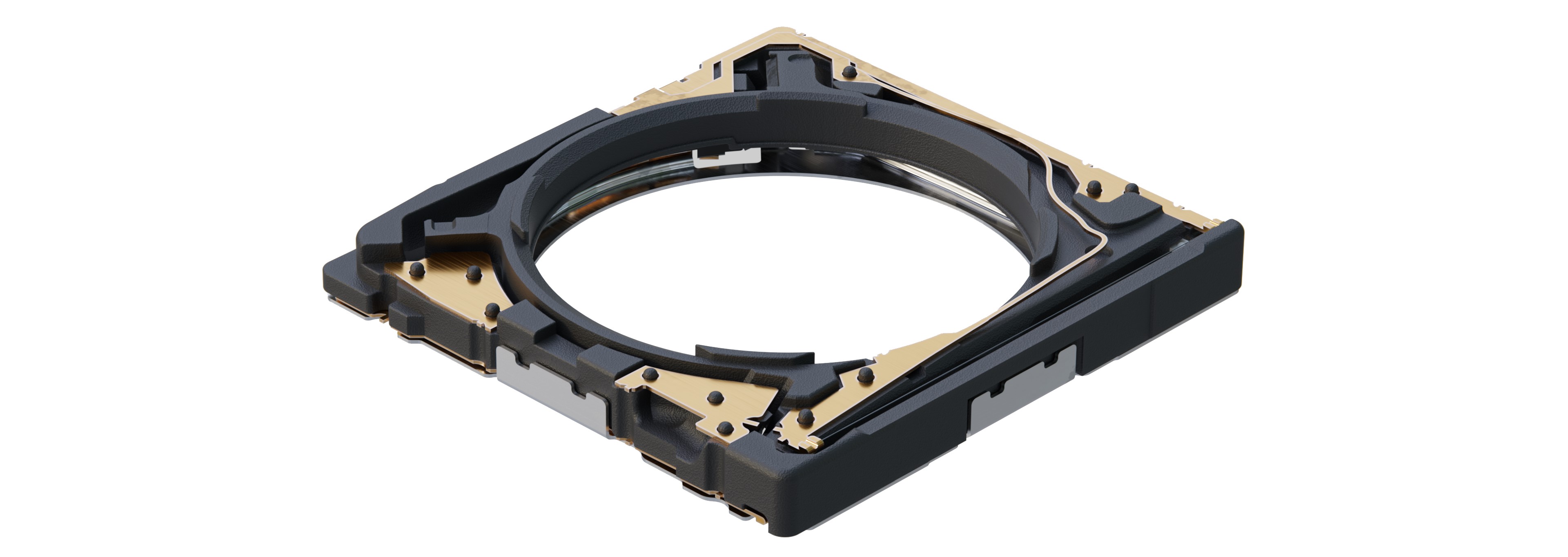

Figure 1: Camera module with SMA AF

SMA advantages in compact devices

The core advantage of SMA materials lies in their inherent microscale benefits, such as a high force-to-mass ratio, which make them ideally suited for size-constrained applications such as smartphones. CML has pioneered the development of SMA microactuator designs and control, catering to a variety of market needs, including optical image stabilisation (OIS) and variable aperture.

As smartphones evolve towards slimmer designs, including folding and flip styles, the necessity for compact, low-height camera modules becomes increasingly critical. CML’s SMA AF actuator is perfectly aligned to meet these trends, achieving a substantial Z height reduction compared to traditional Voice Coil Motor (VCM) AF designs, without compromising on performance.

When SMA AF is combined with an SMA Lens Shift OIS actuator, the total camera height can be reduced by as much as 0.9mm (for a 1/1.3” sensor) compared with an equivalent product using ball-type VCM AF+OIS technology. The SMA AF’s scalability ensures that future actuator variants can be produced with minimal adjustment to existing production lines. The illustration highlights the slim configuration of an SMA AF in combination with an SMA Lens Shift OIS actuator.

When SMA AF is combined with an SMA Lens Shift OIS actuator, the total camera height can be reduced by as much as 0.9mm (for a 1/1.3” sensor) compared with an equivalent product using ball-type VCM AF+OIS technology. The SMA AF’s scalability ensures that future actuator variants can be produced with minimal adjustment to existing production lines. The illustration highlights the slim configuration of an SMA AF in combination with an SMA Lens Shift OIS actuator.

SMA AF actuator overview

The SMA AF actuator cleverly integrates the compact SMA wires with a patented bearing arrangement, achieving actuator Z heights of less than 2.5mm for a 1/1.3” image sensor. This configuration enables over 600µm of AF rated stroke, facilitating macro photography as close as 7cm. The bearing system supports rapid lens movements for lenses weighing more than 1g while maintaining dynamic tilt below 5 minutes of arc (1/12 of a degree). This is achieved due to its novel bearing arrangement that enables good control of the lens tilt despite the low Z height.

Figure 2: SMA AF actuator design

Figure 2: SMA AF actuator design

Customisation

CML has extensive experience in collaborating with diverse partners to develop customised actuators for new products. The SMA AF’s patented bearing arrangement can be tuned to accommodate a wide range of stroke requirements with minimal structural modifications.

Efficient chip utilisation

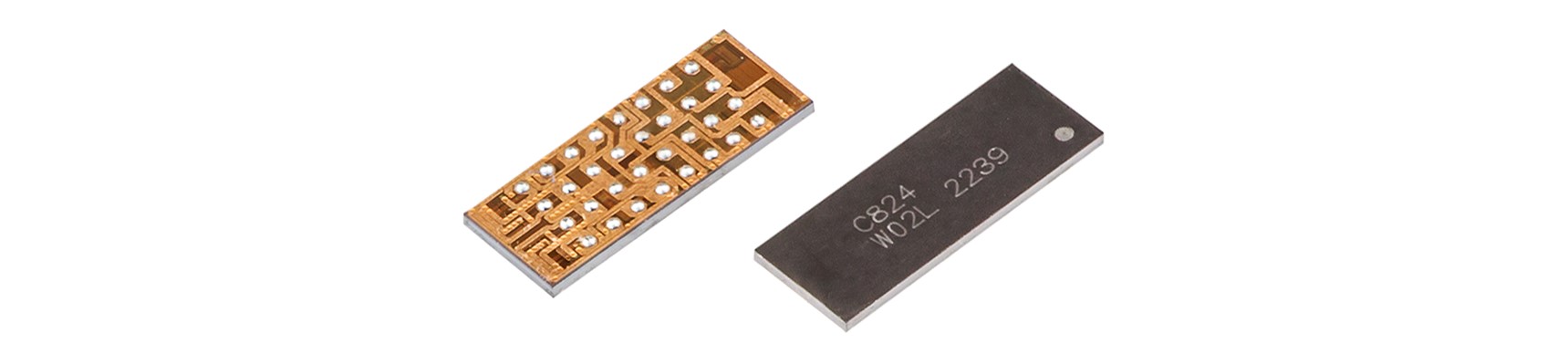

Utilising CML's SMA AF requires only two channels from the 8 available on CML's integrated chip (CM824), allowing room for additional functions such as SMA Lens Shift OIS or SMA Sensor Shift OIS as well as SMA Variable Aperture to be driven from the same chip. This multifunctionality on a single chip underscores the efficiency and compactness SMA technology brings to smartphone camera systems.

Figure 3: CML’s CM824 controller IC

Figure 3: CML’s CM824 controller IC

Magnetic interference and component reduction

Unlike VCM autofocus systems, SMA technology does not generate magnetic interference, offering more flexibility for component placement within smartphone systems. The lens position is controlled by the SMA wires, serving both as the actuation force and the position feedback mechanism, thus eliminating the need for Hall sensors. Remarkably, the SMA AF can be constructed with as few as nine components, including 3 ball bearings.

Low Actuator Mass Benefits

The absence of magnets and other large drive components results in a significantly reduced actuator mass. This reduction not only increases the resonant frequency of the overall camera system, enhancing controllability but also improves reliability. The lower mass decreases the likelihood of damage to end stops and bearing races, further bolstered by the use of larger ball bearings compared to those in VCM AF actuators. These larger bearings distribute contact pressure more evenly in drop scenarios, mitigating bearing damage.

In Summary

CML's groundbreaking use of SMA technology in developing an ultra-slim, high-performance AF actuator marks another milestone in compact device engineering for smartphone cameras. The SMA AF actuator addresses the evolving needs of the smartphone market, promising enhanced camera functionality with minimal size and weight. CML's patented innovations highlight the potential of SMA actuators in enhancing not only smartphone cameras but also a wide range of compact electronic devices. Contact us for more information on the SMA AF.

About CML: Cambridge Mechatronics Limited (CML) is a world-leading developer of mechanical, optical, electrical, silicon, and software designs for system-level solutions using its Shape Memory Alloy (SMA) platform technology. ACTUATOR Systems based on SMA wire (thinner than human hair) can be controlled to submicron accuracy. These actuators are particularly suited to applications requiring high precision and force levels, in a fast, compact, and lightweight design.

For more details about SMA technology and Cambridge Mechatronics, please GET IN TOUCH.