6 Nov 2023

Large angle OIS compensation with SMA camera products

By Stefan Hansen, Marketing Communications Manager

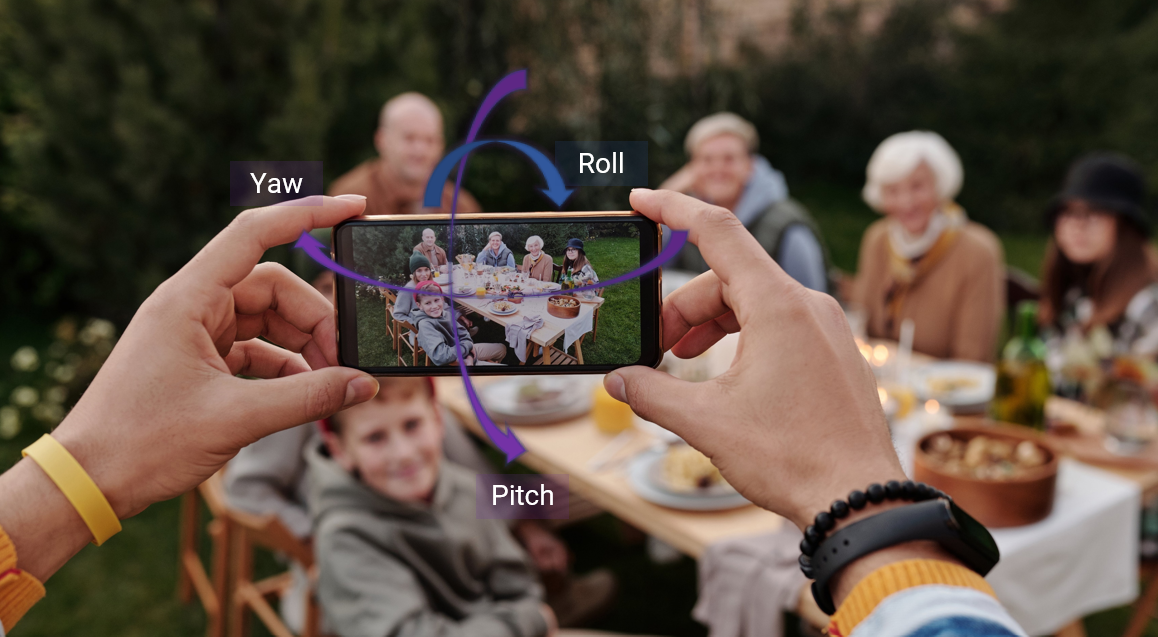

Smartphone users increasingly want to capture high-quality photos and create cinematic video content under varying lighting conditions and whilst on the move. Cambridge Mechatronics Ltd. (CML) is pushing the boundaries of OIS compensation angles to meet these evolving demands of consumers, enabling improved dynamic image and video capture. This article introduces CML's solutions to achieving high OIS compensation angles in smartphone cameras - using shape memory alloy (SMA) technology.

Image credit: Askar Abayev

The need for increased stroke

To design an OIS camera, we need to understand how much OIS amplitude (or actuator stroke) is needed to produce a stable image under different use cases. To date, most OIS products on the market, including SMA OIS actuators, achieve compensation angles of around one degree, sufficient to correct for human handshake under static conditions. However, the landscape of photography and videography is evolving, with users now capturing content on the move, whilst walking, running, cycling, or engaging in various other activities. In these scenarios, the amount of shake amplitude generated often exceeds one degree, thus requiring higher compensation angles to stabilise images effectively.

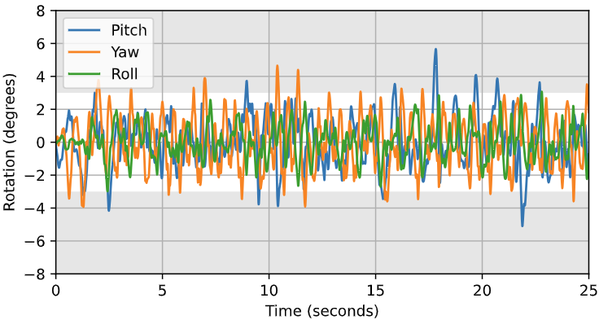

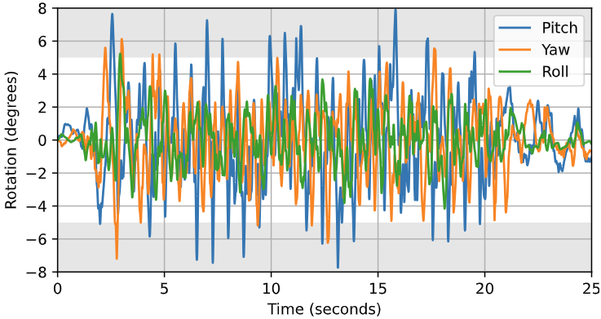

CML has collected amplitude and frequency data under a variety of real-world scenarios to determine the necessary compensation angles.

Figure 1: Gyroscope data showing degrees of amplitude/rotation from walking

Our data shows that for walking, approximately three degrees of pitch and yaw compensation angle are needed, while running can require as much as five degrees. For extreme action scenarios such as mountain biking, even more degrees of rotational compensation angle may be necessary.

Figure 2: Gyroscope data showing degrees of amplitude/rotation from running

Meeting OIS stroke demands with SMA - Amplification

While SMA wires offer the advantage of small size and high force-to-mass ratio, wire strain is typically limited to between 2% and 3% in order to guarantee performance and reliability over product life. This means that a SMA Lens Shift OIS actuator with a wire length of one centimetre, for example, can only move a lens by a total distance of between 200 and 300 microns (i.e. ±100µm to ±150 µm, equivalent to ±1 to ±1.5 degrees assuming a lens effective focal length (EFL) of 5.7mm). This means that without amplification SMA cannot achieve the motion required to completely suppress camera shake when running or even walking, inside an acceptable footprint.

This limitation can be overcome using stroke amplification.

Amplification in existing products

Amplifying the motion from SMA wires is a well-established technique and is already used in some of the world’s leading mobile phone cameras in CML’s SMA Lens shift AF+OIS product (autofocus and optical image stabilisation). This is a mature product in mass production and incorporates 3.5x to 4.5x amplification in the AF direction.

Figure 3: CML’s SMA Lens Shift AF+OIS product

Figure 3: CML’s SMA Lens Shift AF+OIS product

In the SMA Lens Shift AF+OIS product the amplification is achieved by angling the SMA wire with respect to the direction of the intended motion. This angle introduces mechanical gearing into the system.

Amplification increases the motion at the expense of the force delivered. However, the most recent SMA Lens shift AF+OIS products shipping in handsets show that even at large amplifications of 3.5x to 4.5x, the high force of SMA wire is sufficient to move not only the lens but also the mass of a variable aperture actuator at the high motion speeds required for autofocus.

Amplification also reduces the accuracy of the motion. This is due to the fact that when the motion is amplified, any errors in that motion are also amplified. In order to bring the SMA Lens Shift AF+OIS products to market, CML increased the accuracy of its proprietary SMA control firmware to ensure that the high accuracy required for autofocus actuators was maintained despite the large amplificon included in the product.

However, amplification using angled SMA wire is limited to particular directions of motion given a spatial constraint. For example, angled wire cannot be used to amplify OIS motion without an unacceptably large Z dimension. For this reason, CML has developed a new method of amplification - flexure amplification.

Amplification in CML’s next generation products

CML’s flexure amplification involves using a flexure mechanism, to convert the wire’s contraction into an amplified motion as illustrated in the following figure.

Figure 4: Principle of flexure amplification

This figure shows that as the wire contracts under heating, the wire strain is amplified by pivoting around the flexure. The result is motion that is 2-3x greater than the wire's natural contraction length, leading to a significant increase in the range of motion that the lens can achieve.

When this technology is applied to SMA Lens shift OIS and SMA SENSOR SHIFT OIS actuators with motions of up to 800µm (±400µm) can be created. This equates to >±3 degrees of amplitude compensation depending on the lens size and EFL while having minimal impact to the actuator's XY footprint or camera Z height.

This technology can be applied to large 1” cameras as well as periscope/telephoto cameras with confidence knowing that SMA’s ability to deliver high force and accurate motion despite large amplification has been proven in mass production in CML’s Lens Shift AF+OIS product.

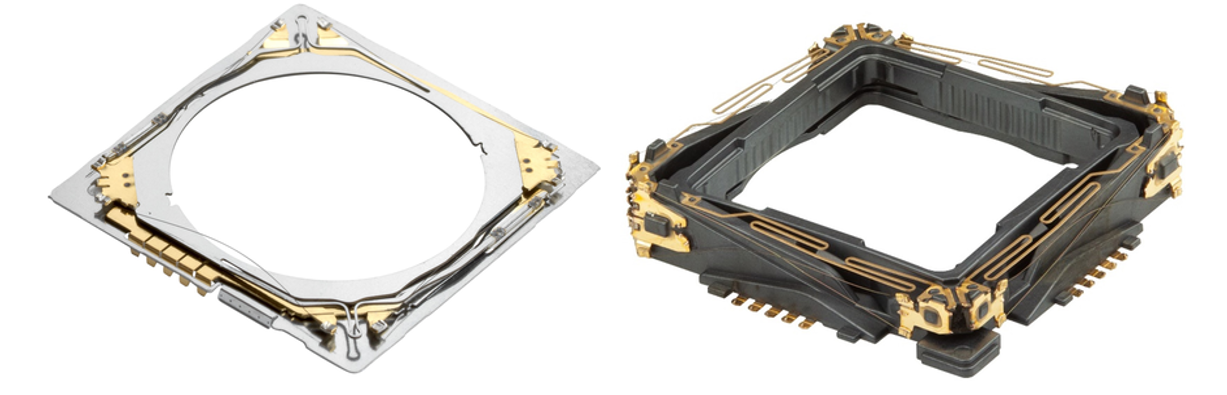

Figure 5: CML's ultra-slim SMA Lens Shift OIS actuator (left) and SMA Module Tilt OIS (right)

The SMA MODULE TILT OIS gimbal stabilisation OIS technology is another example of how CML has amplified the motion of SMA wire to create an innovative new product. This product has been designed to achieve an impressive tilt angle exceeding 5 degrees in pitch and yaw, and 1 degree in roll by employing amplification in the design.

Engineering cutting-edge OIS solutions

CML’s pursuit of higher compensation angles in AF and OIS is a collaborative journey fuelled by real-world use cases. We have examined the challenges of capturing steady shots while walking, running, or engaging in fast-paced activities, and described how SMA actuators can meet these demands by applying the established principle of amplification in new ways.

Regardless of the actuator type, our goal is to provide you with the tools to amplify stroke, increase compensation angles, and elevate optical image stabilisation performance. We recognise that your camera modules are integral to the success of your products, and we are dedicated to ensuring that you have the best OIS technology at your disposal.

CML is your strategic partner in engineering excellence, committed to driving innovation, pushing the boundaries of SMA actuator capabilities, and offering you solutions that empower you to engineer camera modules with best-in-class AF and OIS technology.

About CML: Cambridge Mechatronics Limited (CML) is a world-leading developer of mechanical, optical, electrical, silicon, and software designs for system-level solutions using its Shape Memory Alloy (SMA) platform technology. ACTUATOR SOLUTIONS based on SMA wire (thin as hair) can be controlled to submicron accuracy. These actuators are particularly suited to applications requiring high precision and force levels, in a fast, compact, and lightweight design.

For more details about SMA technology and Cambridge Mechatronics, please GET IN TOUCH.