21 Dec 2023

SMA Lens Shift AF+OIS: How CML Integrates AF and OIS in a single actuator

By René Kist, Director of 8-Wire Development

Optical Image Stabilisation (OIS) is an important feature in premium smartphone cameras, and traditionally OIS and Autofocus (AF) have been enabled using separate actuators. The strong pull of the market for improved image quality has led to broader market traction in mid-range handsets, where, traditionally, only an AF actuator would have been present and the available camera budget is lower. This opens an opportunity for an integrated solution combining OIS and AF that meets flagship performance and mid-range costs points.

The Shape Memory Alloy (SMA) Lens Shift AF+OIS actuator, developed by Cambridge Mechatronics Ltd. (CML), is the world’s first solution that delivers both AF+OIS in a single SMA actuator - offering the best combination of performance and cost-efficiency for the smartphone market. CML’s actuator technology is enabled by its patented controller algorithms residing on a CML controller IC.

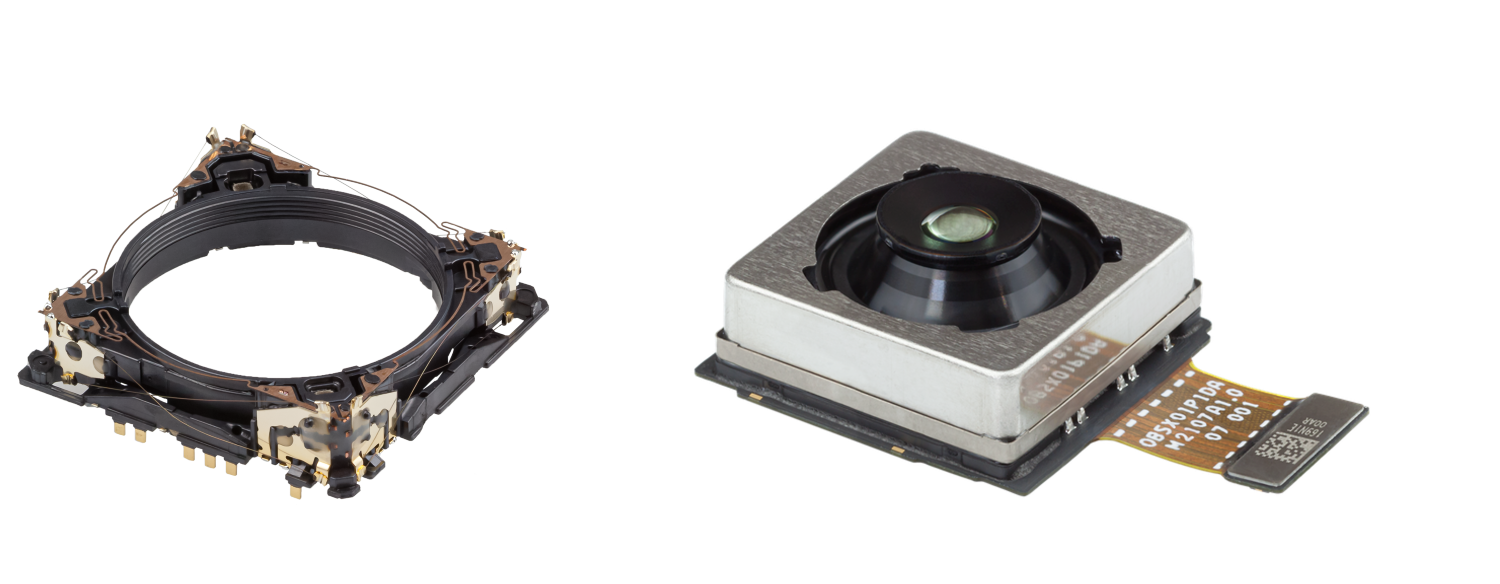

Figure 1: SMA Lens Shift AF+OIS actuator (left) and as a camera module (right)

Figure 1: SMA Lens Shift AF+OIS actuator (left) and as a camera module (right)

The advantages of integrated design with SMA

Unlike most designs, where separate OIS and AF actuators are manufactured before they are combined in the final product, the SMA Lens Shift AF+OIS actuator integrates these functions into a single unit from the start - without the use of bearings. This enables design efficiency, reliability and cost wins in several ways:

1) It reduces the part count by approximately 37%

2) It reduces the complexity of the design and build process.

These factors all help to keep costs down and offer reliability gains.

3) The product can achieve a smaller form factor, which makes it especially attractive for slim handset designs and folded phones.

Innovative wire arrangement in SMA Lens Shift AF+OIS

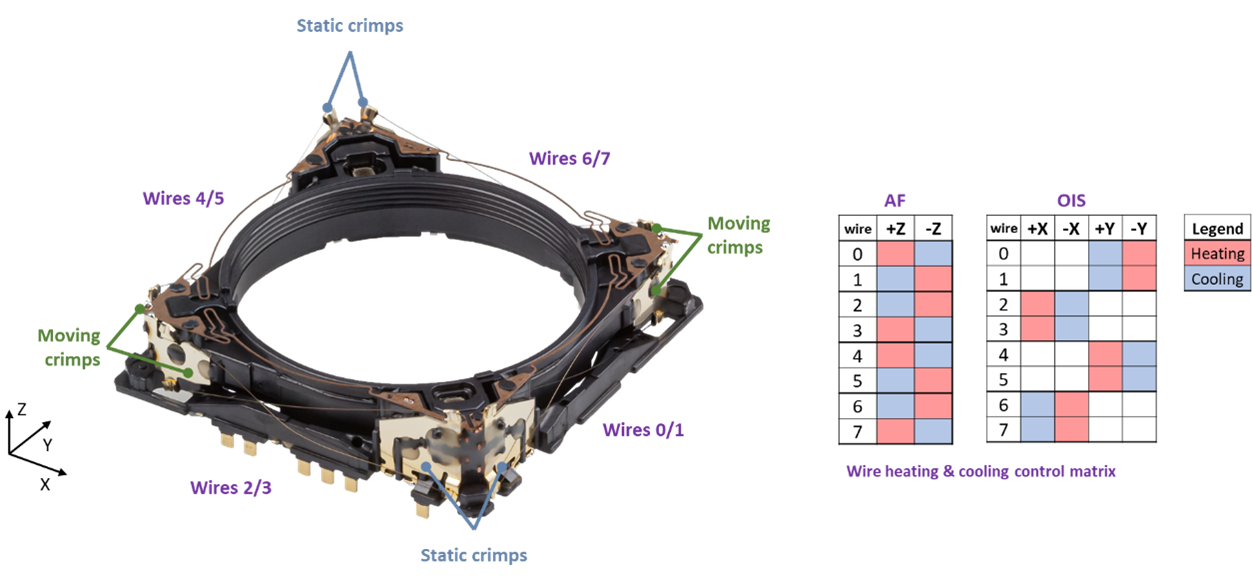

At the core of the SMA Lens Shift AF+OIS is its unique 8-wire arrangement. Each wire in this system pulls in a specific direction, so they combine to control all degrees of freedom, including XYZ translation and tilt.

The wire arrangement also offers a gearing advantage in Z, allowing fast AF transitions. The wires are laid out in a cross-pattern at a relatively shallow angle to the Z-axis, typically between 13 to 15 degrees. This geometry creates a gearing effect in Z of around 4x, which allows for a large stroke and fast-moving speeds - hundreds of microns of travel over tens of milliseconds. Conversely, the 8-wire arrangement allows smooth and accurate movement in the XY plane to meet the actuator motion demands for OIS – tens of microns of travel over hundreds of milliseconds.

Figure 2 shows in detail the wire arrangement and explains how heating (contracting wire) and cooling (extending wire) are used to control the motion for 3 of the possible 6 degrees of motion.

Figure 2: Eight SMA wires suspend the lens carrier controlling 6 degrees of freedom & 2 wire tension groups. Combinations of SMA wires are heated (contracted) or cooled (extended) to give AF and OIS shift movement.

Tilt control: enhancing assembly

The multidirectional control inherent to the actuator gives rise to a unique capability that multicomponent systems or bearing and spring-guided systems don’t have, and that is active tilt control. This ability can be made to work for the benefit of the overall system in a number of ways, including assembly:

Post-assembly tilt correction: during camera assembly, the actuator must be placed over the image sensor in such a position that the lens held inside the actuator is perfectly perpendicular to the image sensor. This is typically achieved by a costly and time-consuming process called Active Alignment (AA), which involves manipulating the actuator with a dextrous robot arm, while monitoring the output from the image sensor for image sharpness before fixing the actuator in its final position. SMA Lens Shift AF+OIS’ tilt control capability offers manufacturers the ability to correct any residual tilt post-assembly. This means potentially higher yields and less reliance on precision in the initial assembly process.

Simplifying the manufacturing process: Looking beyond correcting post-assembly tilt, the SMA system implies the possibility of a revolutionary approach - skipping active alignment altogether. If mechanical tolerances during assembly are within reasonable limits, manufacturers could fix the actuator to the PCB in a passive assembly step and adjust the actuator’s position using the actuator tilt control. This simplifies the production process and removes the requirement for sophisticated alignment equipment.

Video: Introducing Lens Shift AF+OIS (8-wire design)

Further use cases for the 8-wire configuration

With the benefit of a maturing design that has been scaled to various image sensor formats, CML has applied the same wire configuration to introduce gearing in OIS to develop an SMA Module Tilt OIS actuator solution that is capable of higher OIS stroke and amplitude stabilisation. Further design variants exploiting the 8-wire arrangement are being developed.

Benefits in modern smartphone designs

A high force-to-mass ratio is characteristic of SMA actuators. As the market moves towards larger image sensor formats, high-quality glass lens elements and variable apertures, this benefit is becoming increasingly valuable. Folded phones face tighter and more complex design constraints requiring compact actuator solutions. In addition to its compact form factor, SMA is an electromagnetic-free technology so it can safely be placed in close proximity to magnets, antennae and other EMI-sensitive components.

Cambridge Mechatronics’ SMA Lens Shift AF+OIS represents a significant advancement in smartphone camera technology. By integrating AF and OIS into a single unit, we offer a solution that is compact and cost-effective. As the industry continues to evolve, the versatility and innovative design of SMA Lens Shift AF+OIS place it at the forefront of camera technology, applicable for flagship as well as mid-range handset ranges. When combined with CML’s dedicated controller IC, the best performance and latest features are achieved.

About CML: Cambridge Mechatronics Limited (CML) is a world-leading developer of mechanical, optical, electrical, silicon, and software designs for system-level solutions using its Shape Memory Alloy (SMA) platform technology. ACTUATOR SOLUTIONS based on SMA wire (thin as hair) can be controlled to submicron accuracy. These actuators are particularly suited to applications requiring high precision and force levels, in a fast, compact, and lightweight design.

For more details about SMA technology and Cambridge Mechatronics, please GET IN TOUCH.