6 Sep 2023

How Shape Memory Alloy is used in high-tech applications

By Josh Carr, Senior Business Development Manager

Cambridge Mechatronics Ltd. (CML) is a global leader in the design and control of shape memory alloy (SMA) actuators. This article details the industries that are adopting SMA, sharing insights into two existing applications and introduces emerging applications that CML is enabling.

In 1959, scientists at the United States Naval Ordinance Laboratory discovered an alloy of with some intriguing properties. This was the birthplace of super-elastic Shape Memory Alloy materials. The most common memory metal is called Nitinol, consisting of equal parts of nickel and titanium, however, other compositions also exist. The fundamental material properties (lightweight, compact, high force-to-weight ratio and biocompatibility) mean that SMA materials have found applications in several high-tech industries.

A property of SMA materials is their capability to undergo large strain deformations and then recover to their original shape without permanent damage. This is known as super-elasticity. When the engineers at NASA needed to find a suitable material for the tyres of the Mars rover they turned their attention to Nitinol. In this application, the materials’ super elastic property allows the tyres to withstand significant strains encountered when driving over rough, rocky terrain, and subsequently recover their original shape without incurring any damage. In the harsh Martian environment, traditional pneumatic tyres could not be used, and so SMA tyres serve as a reliable and durable solution. This technology will soon become available to a much wider audience, as The SMART tire company has developed a bike tyre version to make punctures a thing of the past.

Mars Rover tyre and the SMA bike tyre from the SMART tire company

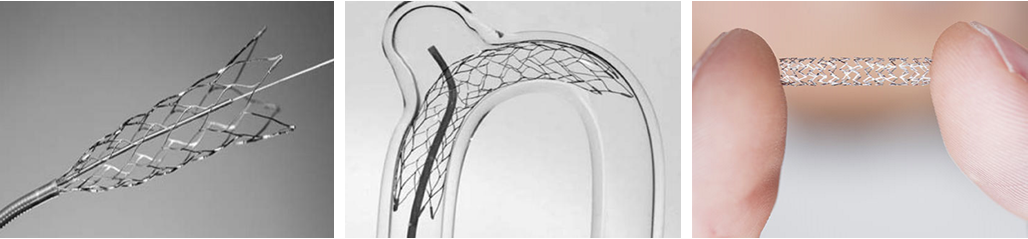

The super-elasticity of SMA is also being used in the medical field. Many stents holding arteries open are made from Nitinol. The remarkable elasticity of the material means that they can be compressed to enable easy insertion and subsequently they spring back to their open shape once deployed within the human body. Additionally, Nitinol’s biocompatibility ensures patient safety and opens up the potential for other medical applications in the future.

Nitinol stents

Nitinol stents

Emerging uses for SMA

Alongside the super-elasticity, there is a similar property that is the shape-memory effect. This property means that SMA material contracts when heated above a transition temperature. By electronically controlled heating and cooling of an SMA wire thinner than a human hair, fast and precise actuation can be achieved. The material phase transition during the heating cycle generates a high force-to-weight ratio which enables loads such as optical elements to be moved. CML alone is able to control the speed and precision of miniature SMA actuators necessary for smartphone applications including optical image stabilisation (OIS) and autofocus (AF) through closed-loop control.

Customers select SMA technology owing to its small footprint, excellent performance, lack of electromagnetic interference and the high force-to-weight ratio. Cambridge Mechatronics is already successful in the smartphone camera industry, with >50 million units shipped across many brands, and is now applying this transformative technology with a wide range of applications spanning multiple industries, including:

- VR/AR Displays: SMA can be employed to develop dynamic and adaptive lenses or display elements. The ability to precisely position optical components can improve the performance of virtual and augmented reality displays, enhancing the user experience.

- Haptics: In the world of touch feedback technology, SMA can be utilised to create more tactile and lifelike experiences. They can produce real-time and localised mechanical responses in devices, making virtual interactions feel more real and intuitive.

- Fluidics: In fluidic systems, SMA can be employed in miniature pumps and valves. The control of their shape memory properties can help in maintaining optimal flow rates or reducing the size of miniature pumps.

- Consumer Electronics: CML is developing camera actuators that can enhance image resolution beyond the image sensor limits (super resolution) and designs for display hinges for laptops and tablets.

At CML, we offer full product development support: from developing the mechanical design to providing driver chips and essential control firmware for the actuators. We license our technology to manufacturing partners, who mass manufacture the mechanical actuator with high yields ready to be combined with CML’s own drive silicon for the global market.

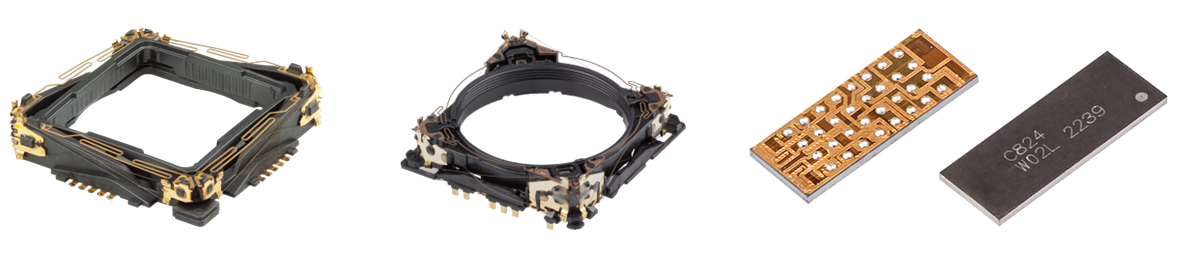

Cambridge Mechatronics SMA actuators for optical image stabilisation and autofocus with corresponding driver chips

The material properties of SMA make it a fascinating material which is already being used in a diverse range of high-tech applications. With CML’s closed-loop control algorithms, in the future we expect the number of applications to grow quickly in many different markets including haptics, medical devices and beyond. We are committed to delivering the potential of SMA into these new and inventive markets. Our enthusiasm is not just about harnessing the potential of SMAs but also about delivering value to consumers and industries alike.

As we continue to explore and innovate, SMA promises to be particularly exciting, given its versatility and potential across such diverse domains. Our operating model involves working closely with our partners and customers; please get in touch if you have an application in mind that we can help you with.

ABOUT CML: Cambridge Mechatronics Limited (CML) is a world-leading developer of mechanical, optical, electrical, silicon and software designs for system-level solutions using its Shape Memory Alloy (SMA) platform technology. Solutions such as ACTUATORS based on SMA wire (which is as thin as a human hair) can be controlled to the accuracy of the wavelength of light. These actuators are particularly suited to applications that require high levels of precision and force, in a fast, compact and lightweight design.For more details about SMA technology and Cambridge Mechatronics, please GET IN TOUCH.