30 Sep 2022

Cambridge Mechatronics introduces SMA Sensor Shift OIS actuator for optical image stabilisation (OIS)

Cambridge Mechatronics Ltd (CML), which continues to lead the way in the development of Shape Memory Alloy (SMA) technology, is pleased to announce the launch of our Sensor Shift OIS actuator for optical image stabilisation (OIS).

With smartphone cameras adopting many of the features of state-of-the-art digital stills cameras, promising Hollywood quality movie making, the requirement for optical image stabilisation (OIS) has never been more vital. One solution, SMA Sensor Shift OIS, moves the image sensor in response to smartphone handshake motion. By moving the image sensor instead of the lens, heavy lenses and variable apertures can be used. In addition, rotational motion can now be stabilised, enabling 5-axis compensation.

The main challenge in a sensor shift actuator is the requirement to move the image sensor whilst simultaneously connecting it to the handset. Traditional voice coil motor (VCM) actuators use magnets and electromagnetic coils, which are limited in the force they can generate. Further limitations of VCM include components and assembly processes, and the requirements to move both the image sensor and interconnect, increasing the camera footprint and bump-out size. Additionally, VCM designs don’t allow for the 5th axis of motion, roll, as they are prohibited by one smartphone brand’s patent portfolio, limiting usage to the wider market.

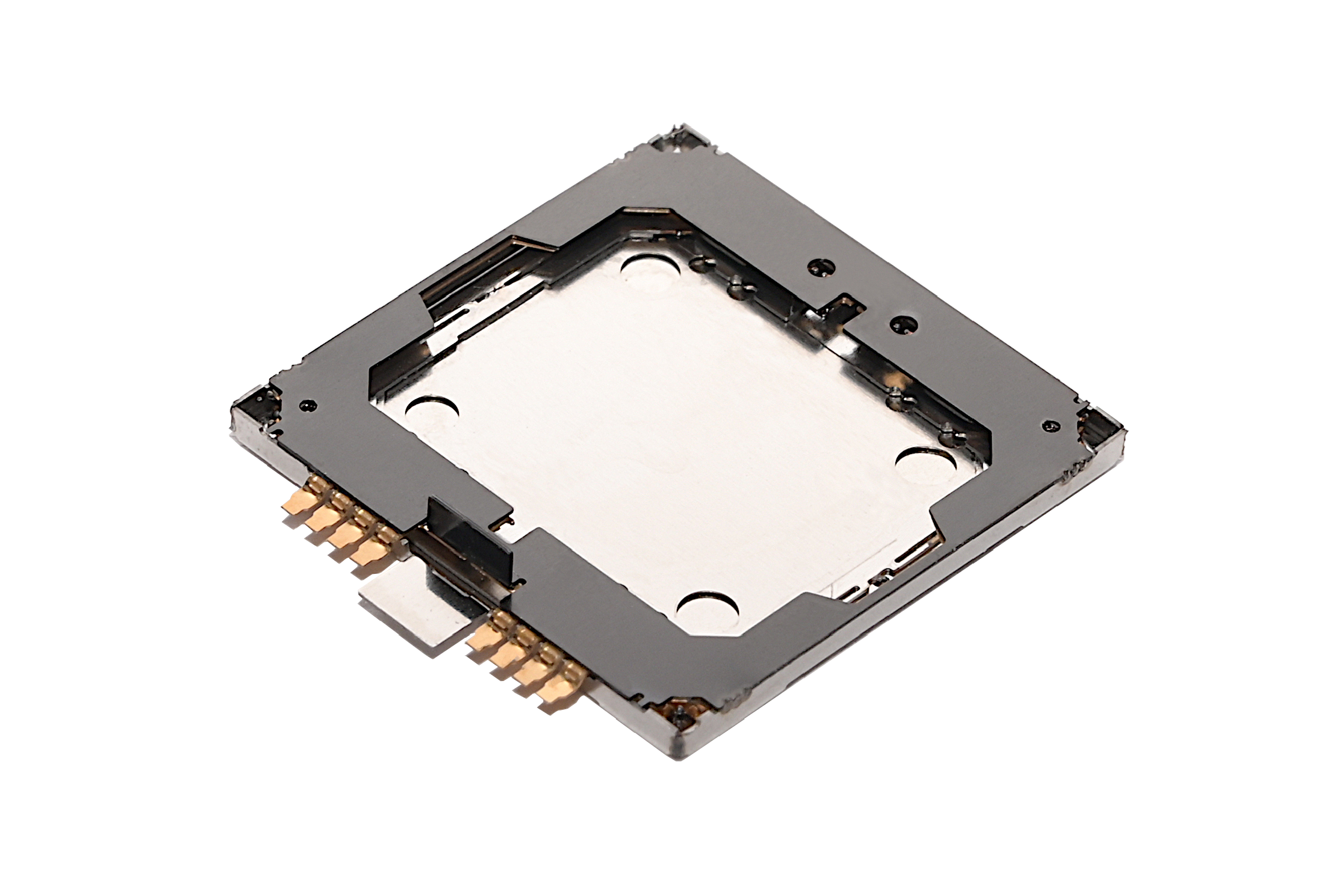

CML has developed the Sensor Shift OIS actuator design controlled using our SMA wire. The actuator uses a simple design of 4 SMA wires of 25um diameter in a square configuration around the image sensor. These SMA wires contract upon heating above a transition temperature - the image sensor position and motion are therefore achieved by controlling the wire lengths thermally. CML’s designs ensure no compromise is made to the camera performance.

This approach means that CML’s solution does not have many of the drawbacks you get with a VCM design instead providing 3-axis or SLR-style 5-axis shake compensation, a reduction in footprint at -35% and our SMA wires generate a high force which means a wide range of interconnect materials and designs can be used, giving smartphone makers greater flexibility.

Additionally, CML’s unique driver chip and control technology removes the need for the position (Hall) sensing technologies that VCM requires and enables customer bespoke features. Also, CML’s design does not use magnets and eliminates the potential of magnetic interference. CML fully supports its customers with full system integration, including driver chip and firmware which can offer bespoke features.

CML’s SMA sensor shift actuator designs accommodate a range of image sensor formats and are now widely available for sampling from proven and experienced supply chains. CML’s 4-wire designs are reliable and have shipped in >45 million handsets to date, routinely with top camera quality scores from independent testing. The first smartphone camera incorporating CML’s new SMA sensor shift technology was released in the flagship handset of a major brand early in 2022.

To learn more about sensor shift, visit our technical page.

About CML: Cambridge Mechatronics Limited (CML) is a world-leading developer of mechanical, optical, electrical, silicon and software designs for system-level solutions using its Shape Memory Alloy (SMA) platform technology. Solutions such as ACTUATORS based on SMA wire (which is as thin as a human hair) can be controlled to the accuracy of the wavelength of light. These actuators are particularly suited to applications that require high levels of precision and force, in a fast, compact and lightweight design.

For more details about SMA technology and Cambridge Mechatronics, please GET IN TOUCH.