11 Sep 2023

Benefits of Continuous Variable Aperture using Shape Memory Alloy

By Steve Bunting, Staff Engineer

The introduction of Continuous Variable Aperture (CVA) technology for smartphone photography has sparked a significant conversation about its merits. Here we compare some of the advantages of using Shape Memory Alloy (SMA) for variable aperture compared to Voice Coil Motor (VCM) technology.

Prior to Huawei’s release of the Mate 50 Pro, variable apertures in smartphones provided, at most, a choice between two aperture sizes: either a large aperture for low light images, or a mid-size aperture for bright light conditions where a larger depth of field (DoF) is preferable. For example, Samsung previously used a 2-stop VA with aperture sizes of F2.4 and F1.5. This provided an aperture best for general photography (F2.4) and a larger aperture (F1.5) for low light images. The combination of low-light and large DoF photography can be supported by optical image stabilisation (OIS) for longer exposures and sensor sensitivity settings (ISO).

As image sensors and lens size increase, the need for 3 or more aperture choices becomes more important for achieving the best depth of field control and photographic creativity. A lens that matches a 1” image sensor would benefit from a continuous variable aperture (CVA) that can provide at least 4 aperture sizes.

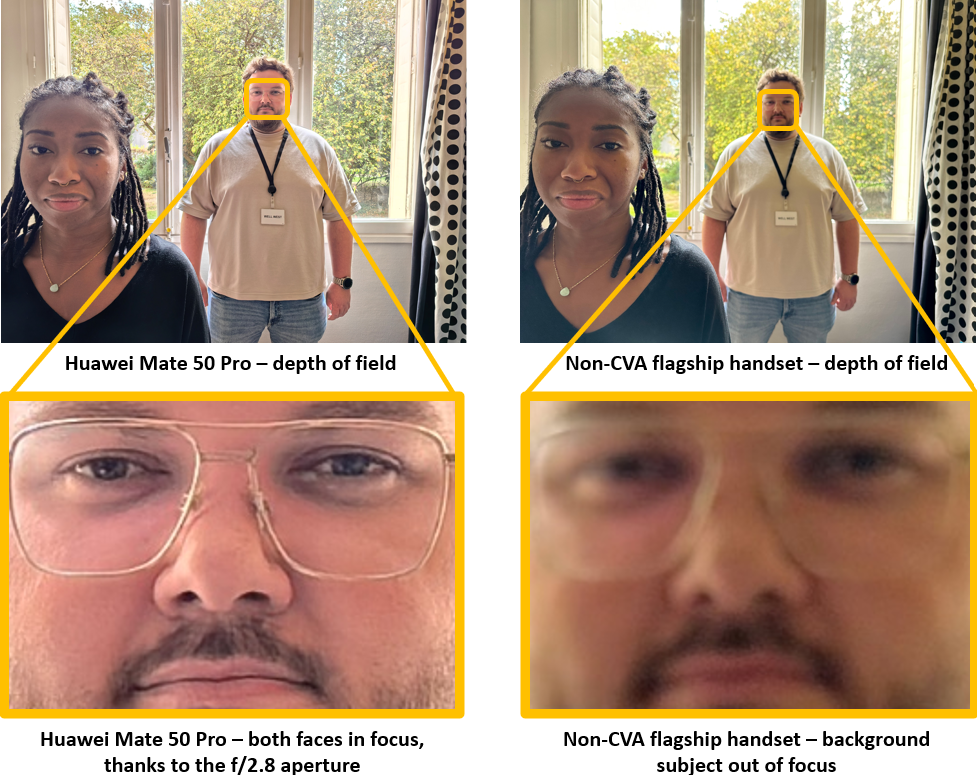

The image below shows the impact of using a variable aperture with a large image sensor. The Mate 50 Pro is compared to a flagship handset without CVA where the aperture is fixed leading to a shallower depth of field and blurring outside of the focal plane.

Image source: DxOMark

At the time of writing, the Huawei Mate 50 Pro, P60 series, Nova 11 Ultra and Mate 60 Pro are the only handsets with CVAs. The Mate 50 Pro and P60 Pro received top DxOMark camera scores at the time of release. These handsets provide 10 aperture sizes with automatic scene-based switching or user-selectable aperture sizes when the camera app is in Pro mode.

In standard photo mode, the camera app selects an aperture of F1.4 for dark scenes to allow maximum light to reach the image sensor. F2 is selected for most scenes and allows a good balance of light capture and depth of field to produce pleasing images. An aperture of F4 is automatically selected for scenes with good light conditions that have a depth of field requirement like group shots or scenes with subjects in the near and far field.

Benefits of SMA over Voice Coil Motor (VCM)

VCM Variable Aperture actuators have experienced issues that can be avoided when using SMA designs.

- The proximity of magnets external to the VCM VA camera system has raised performance concerns from some smartphone manufacturers. An SMA CVA has no magnets and is free from electromagnetic interference so it is easier to position the camera system within the handset without any system performance compromises.

- SMA technology consumes less power, contributing to longer battery life for your device. SMA maintains aperture position with Zero Hold Power (ZHP) technology, providing high stability when the handset is in motion, without continuous power draw.

- VCM VAs are relatively larger than SMA CVAs and can impact the size requirement of the external camera bump-out.

- VCM VAs are heavy and limit AF and OIS performance. SMA VA is between 4-8x lighter than VCM CVA.

Size

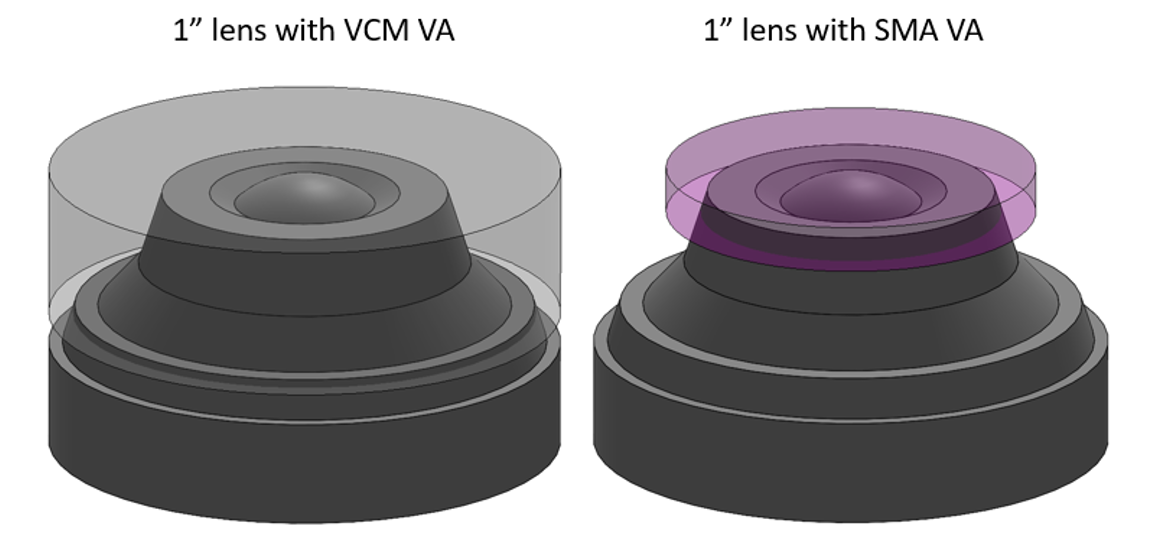

Adding VA to a lens increases its diameter and height which forces handset designers into industrial design compromises. The image below shows a 1” lens with a VCM CVA and an SMA CVA. The smaller SMA design provides handset designers with greater integration flexibility.

Cambridge Mechatronics has analysed the impact of VCM VA and SMA CVAs on the lens diameter and handset bump-out dimensions. In the case of a 1” lens size, the VCM CVA designs currently available would add up to 8.9mm depending on the handset particulars. By comparison, an SMA Variable Aperture design by Cambridge Mechatronics would add only 2.5mm. In short, SMA CVA will fit into existing bump-out dimensions, whereas a VCM VA will cause the bump-out to increase in size.

Driven by increasing image sensor and lens size, handset bump-outs have increased in height and footprint. However, handset thickness is becoming a concern with Tier 1 brands who are actively looking to reduce the bump-out thickness and size. This can be enabled through the use of SMA VCAs.

Conclusion

As image sensors and lenses are increasing in size, handset makers are adopting variable apertures to ensure there is no loss in photographic quality due to depth of field limitations inherent in a single aperture design. The ability to adjust the aperture allows more light to be collected in low light while the depth of field can be automatically increased or manually controlled in standard lighting conditions.

Due to z-height increase limitations, the trend to increasing image sensor format and therefore camera size is expected to slow. This will apply increasing pressure on other ways to enhance camera performance. Variable aperture is a strong contender as a technology that can offer differentiation and performance enhancement.

The benefits that SMA bring are low power, small form factor, light-weight actuators that are capable of high force without any electromagnetic interference; the high force enables high production yield and benefits related to shake noise and power consumption.

About CML: Cambridge Mechatronics Limited (CML) is a world-leading developer of mechanical, optical, electrical, silicon and software designs for system-level solutions using its Shape Memory Alloy (SMA) platform technology. Solutions such as ACTUATORS based on SMA wire (as thin as a human hair) can be controlled to the accuracy of the wavelength of light. These actuators are particularly suited to applications that require high levels of precision and force, in a fast, compact and lightweight design.

For more details about SMA technology and Cambridge Mechatronics, please GET IN TOUCH.