12 May 2025

Zero Hold Power with SMA: Power-saving technology for variable apertures in smartphones

By Adam South, Senior Mechanical Engineer

The demand for Variable Aperture (VA) camera systems is growing in smartphones, along with the need for more compact and more power-efficient actuators. Cambridge Mechatronics Ltd. (CML) has developed a unique feature for Shape Memory Alloy (SMA) actuator technology: SMA Zero Hold Power (SMA-ZHP), which allows actuators to hold their position without consuming power. This article explores how SMA-ZHP benefits SMA-VA by reducing energy use and improving efficiency while also offering advantages for other space-constrained applications like head-mounted devices (HMDs) and medical wearables.

What is CML’s SMA - Zero Hold Power?

SMA-ZHP is an optional design feature available in some of Cambridge Mechatronics' SMA actuators. When enabled, the actuator can switch to a ZHP mode, allowing it to hold its position with zero power consumption. This contrasts with conventional actuators, like Voice Coil Motors (VCMs), which require continuous power to maintain their position. An SMA actuator with the SMA-ZHP technology can be used as a normal SMA actuator, but once in position, the ZHP mode can be activated and power can be switched off entirely, saving energy until another movement is needed. ZHP can be activated or deactivated as required, depending on the actuator usage to avoid any impact on transition times.

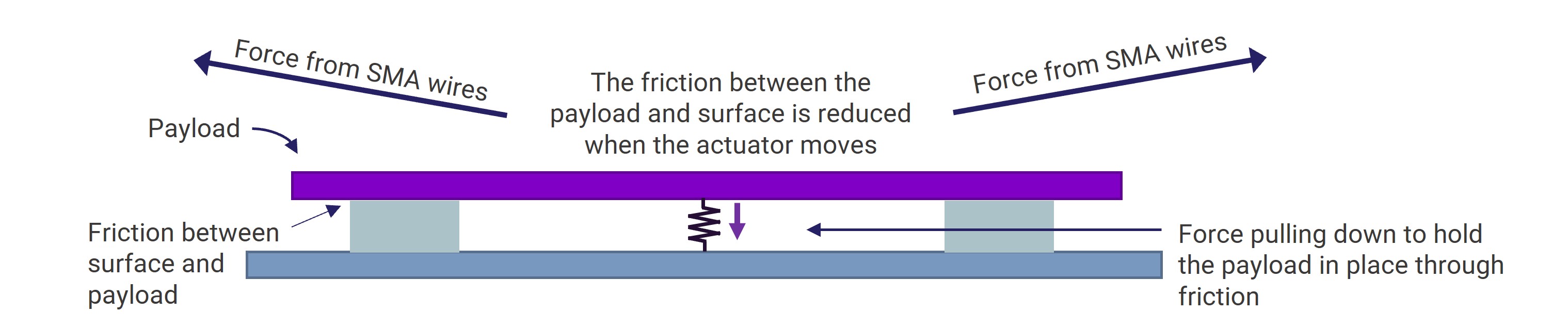

This feature is implemented through both mechanical design and control firmware, and is achieved using friction elements in the actuator assembly. When combined with the high force output of SMA wires, the actuator can overcome the friction to move, then remain stationary when powered off. SMA's high force-to-mass ratio enables this capability which is not possible with VCM actuator technology. The high frictional force also ensures that the components stay in the correct place when there are external forces applied, even when the device is switched off.

ZHP is a versatile feature that can be integrated across a range of SMA actuator applications, including variable aperture, autofocus, AR/VR headsets and even medical devices such as insulin patch pumps.

Figure 1: The mechanical principle of ZHP relies on friction and preload forces (via springs or similar components), with SMA actuators delivering smooth and precise motion (left and right in the example above) by reducing the friction when moving the actuator moves.

Why ZHP matters for variable aperture in smartphone cameras

Power efficiency is a critical consideration in smartphone camera design, especially for features like variable aperture, where transitions are infrequent, but the aperture must hold its position reliably. Traditional actuators, such as VCMs, require constant power to maintain the selected f/stop, adding to energy consumption and heat dissipation.

Cambridge Mechatronics’ SMA actuators with ZHP mode solve this by requiring power only when changing aperture size. Once the desired position is reached, the actuator holds it passively, cutting power draw to zero during filming, taking photos or when the camera is in preview mode. For example, in a typical 3-minute period of camera use with 5 aperture transitions, ZHP reduces average actuator current from currently over 25 mA (with VCM) to under 0.1 mA (with SMA) - a power saving of more than 99%. Lower power also means less heat, helping maintain thermal stability across the camera system, including the lens.

ZHP-enabled SMA actuators also offer integration benefits. Free from large magnets and coils, they generate no electromagnetic interference (EMI), simplifying system design and avoiding conflicts with nearby components such as VCM AF or OIS.

Another advantage is mass. SMA-based VA systems are about 70% lighter than VCM alternatives (for a 1” sensor). This translates to reduced power consumption for autofocus (AF) and optical image stabilisation (OIS) and better performance from lower inertia to allow for faster focus times, improved OIS suppression, and easier implementation in slim, lightweight smartphone designs.

Video: SMA Variable Aperture product video

Proven applications

ZHP has been successfully demonstrated across a range of applications, from HMDs for AR/VR/XR to prototype designs for medical wearables and variable apertures in smartphone cameras.

In head-mounted displays, SMA actuators with ZHP can control lens elements or display modules, holding focus or alignment without consuming power to maintain a particular position. This is vital for preserving battery life in always-on, portable systems.

In medical wearables, such as insulin patch pumps, ZHP offers a way to maintain dosing mechanisms in position passively, improving both reliability and energy efficiency. The result is a more compact, comfortable, and longer-lasting device for patients.

Summary

CML’s Zero Hold Power feature, enabled by our SMA actuator platform technology, offers a clear advantage for applications that require power-efficient, compact, and precise motion control. For variable apertures in smartphones, ZHP provides a pathway to significant power savings and simplified system design.

This same benefit extends to head-mounted displays and medical wearables, where battery life and component size are just as critical. With ZHP, SMA actuators unlock new performance possibilities in next-generation devices, offering OEMs and component suppliers a feature that addresses both engineering challenges and market demands.

About CML: Cambridge Mechatronics Limited (CML) is a world-leading developer of mechanical, optical, electrical, silicon, and software designs for system-level solutions using its Shape Memory Alloy (SMA) platform technology. ACTUATOR SOLUTIONS based on SMA wire (thinner than human hair) can be controlled to submicron accuracy. These actuators are particularly suited to applications requiring high precision and force levels, in a fast, compact, and lightweight design.

For more details about SMA technology and Cambridge Mechatronics, please GET IN TOUCH.